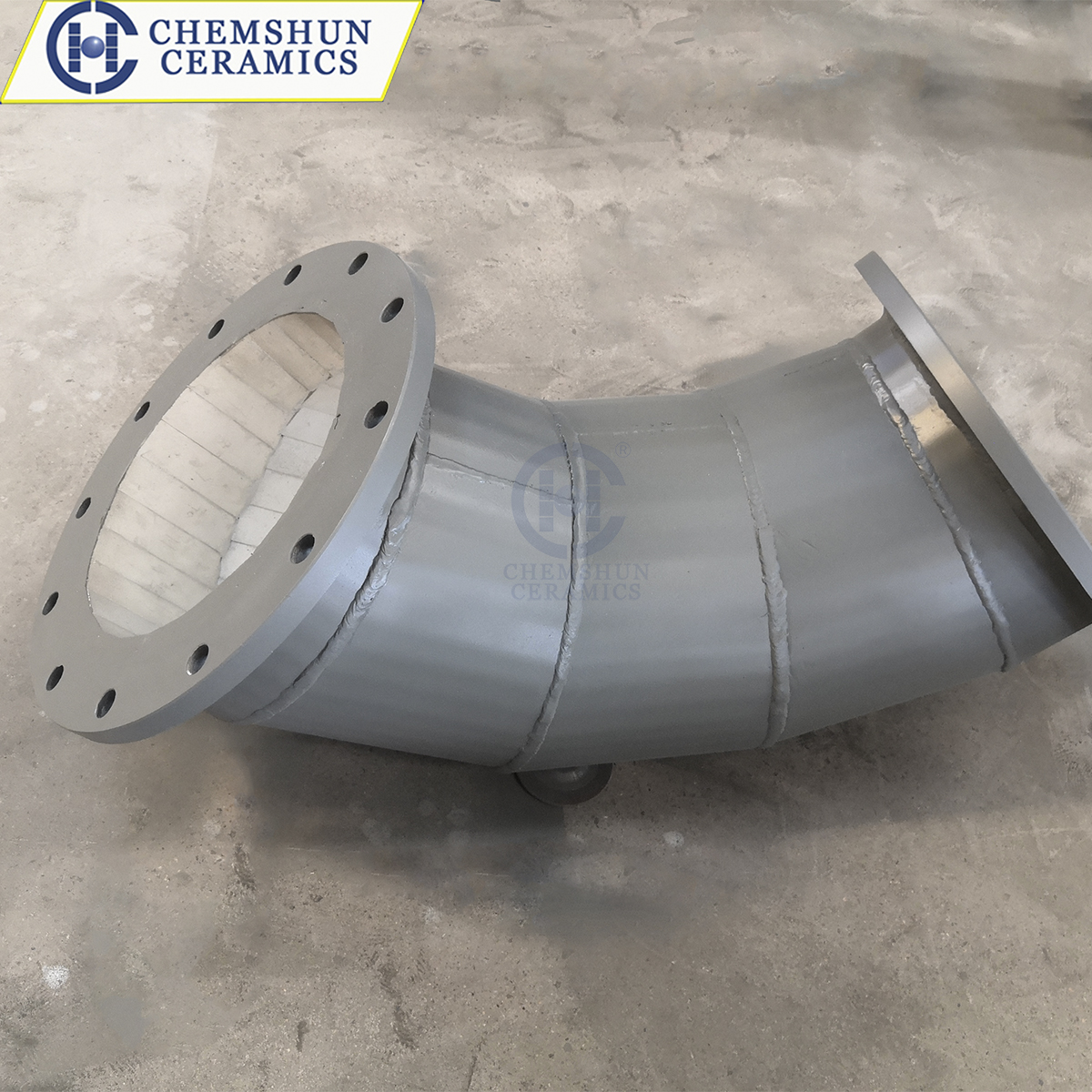

Ceramic Lined Composite Steel Pipe

Khoom Advantage

> Lub neej ntev thiab kev saib xyuas dawb ua haujlwm.

> Tsis muaj kev cuam tshuam kev lag luam lossis kev tsim khoom poob.

> Tsis muaj kab mob ntawm cov khoom siv vim kev puas tsuaj, sib tov lossis oxidation.

> Physiologically harmless, haum rau cov khoom noj.

> Smooth nto kom ua tau zoo flowability thiab kom tsis txhob plugs.

> Tsis muaj cov khoom nchuav los ntxuav.

Cov ntaub ntawv tshuaj

| S. No. | Yam ntxwv | Chav tsev | Cheem 92 | Cheem 92 | Cheem 95 | Chemshun ZTA |

| 1 | Alumina Cov ntsiab lus | % | 92 | 92 | 95 | 70-75 ib |

| ZrO2 | % | 25-30 | ||||

| 3 | Qhov ntom | g/cc | ≥3.60 | ≥3.60 | 3, 65 | ≥4.2 |

| 4 | Xim | - | Dawb | Dawb | Dawb | Dawb |

| 5 | Kev nqus dej | % | 0.01 | 0.01 | 0 | 0 |

| 6 | Flexural zog | Mpa | 270 | 300 | 320 | 680 |

| 7 | Moh tus ceev | Qib | 9 | 9 | 9 | 9 |

| 8 | Pob zeb Zoo Hardness | HRA | 80 | 85 | 87 | 90 |

| 9 | Vickers Hardness (HV5) | Kg / hli 2 | 1000 | 1150 | 1200 | 1300 |

| 10 | Fracture Toughness (Min) | MPa.m1/2 | 3-4 | 3-4 | 3-4 | 4-5 |

| 11 | Compressive zog | Mpa | 850 | 850 | 870 ib | 1500 |

| 12 | Thermal Expansion Coefficient (25-1000 ℃) | 1 × 10-6 / ℃ | 8 | 7.6 | 8.1 | 8.3 |

| 13 | Ua haujlwm kub siab tshaj plaws | ℃ | 1450 | 1450 | 1500 | 1500

|

Kev pabcuam

Peb txais kev cai txiav txim.

Yog tias koj xav paub ntau ntxiv txog cov khoom lag luam, thov koj xav tiv tauj peb thiab peb yuav them koj cov khoom tsim nyog thiab cov kev pabcuam zoo tshaj plaws!