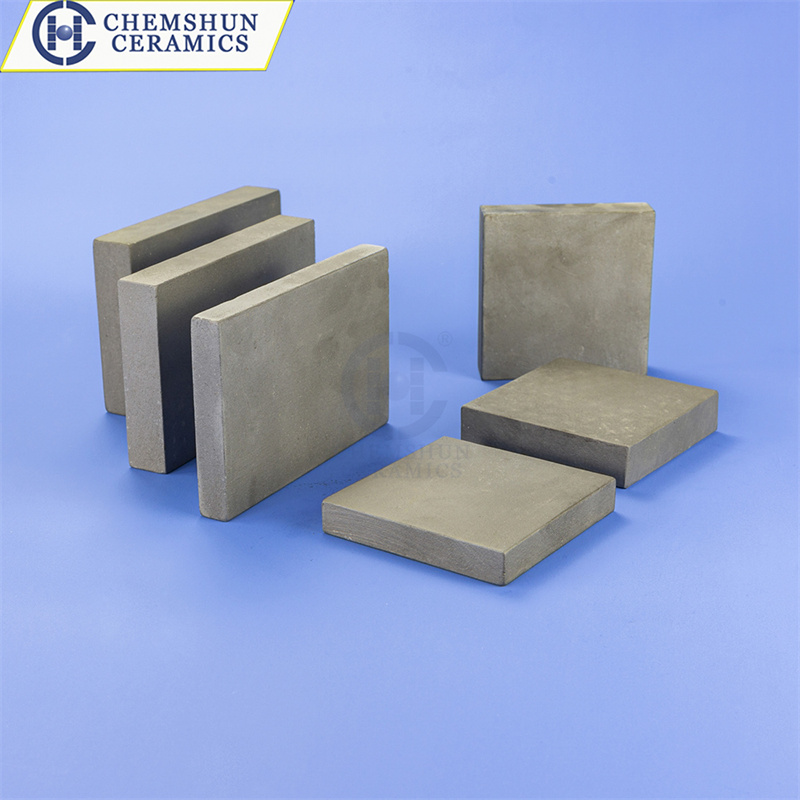

Reaction Bonded Silicon Carbide Pobzeb

Qhov zoo ntawm Reaction Bonded Silicon Carbide

1) Tsawg ceev.

2) Corrosion kuj.

3) Hnav tsis kam.

4) oxidation tsis kam.

5) Abrasion tsis kam.

6) Zoo thermal poob siab tsis kam (vim qis thermal expansion coefficient thiab siab thermal conductivity).

7) Lub zog zoo heev ntawm qhov kub thiab txias.

8) Kev tswj qhov zoo ntawm cov duab nyuaj.

Hnav Resistant khoom: Silicon carbide phaj, Silicon carbide cib, yeeb nkab hauv ob sab phlu, yeeb nkab Cone, cyclone, thiab lwm yam.

Kiln rooj tog: Phaj, Beam, Roller, Burner Nozzle, Round beam, square beam, qhov beam.Crucible, Sagger, thiab lwm yam.

Lwm yam: Desulfurization nozzles

Daim ntawv thov ntawm Reaction Bonded Silicon Carbide:

Reaction bonded silicon carbide tau ua pov thawj tias yog ib qho khoom siv zoo tshaj plaws rau kev hnav daim ntaub ntawv xws li cov yeeb nkab liner, Nozzles, ntws tswj chokes thiab loj hnav cov khoom hauv mining nrog rau lwm yam lag luam.

Main Parameter

| Cov khoom | Chav tsev | SiSiC/RBSIC |

| Bulk ntom ntom (SiC) | V01% | ≥85 |

| Qhov ntom ntom | g/cm3 | 3.01 Nws |

| Pom tseeb porosity | % | 0.1 |

| Modulus ntawm rupture ntawm 20 ℃ | Mpa | 250 |

| Modulus ntawm rupture ntawm 1200 ℃ | Mpa | 280 |

| Modulus ntawm elasticity ntawm 20 ℃ | Gpa | 330 |

| Fracture toughness | Mpa * m1/2 | 3.3 |

| Thermal conductivity ntawm 1200 ℃ | ua wm-1.k-1 | 45 |

| Thermal expansion ntawm 1200 ℃ | ib x10-6/ ℃ | 4.5 |

| Thermal shock tsis kam ntawm 1200 ℃ | Zoo heev | |

| Coefficient ntawm tshav kub tawg | <0.9 | |

| Max.ua haujlwm kub | ℃ | 1350 |

Loj

tuaj yeem kho raws li cov neeg siv khoom xav tau.

Kev pabcuam

Peb txais kev cai txiav txim.

Yog tias koj xav paub ntau ntxiv txog cov khoom lag luam, txais tos hu rau peb thiab peb yuav them koj cov khoom tsim nyog thiab cov kev pabcuam zoo tshaj plaws!