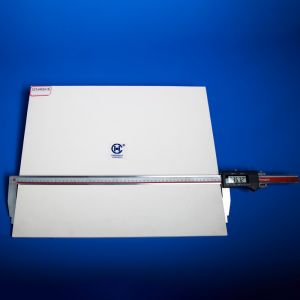

99.7% Alumina Ceramic Baseboard

Daim ntawv thov

Raws li Alumina Substrate rau LCD vaj huam sib luag (PFD, PDF, TFT…) tsim khoom.

Rau Loj LCD kev lag luam iav substrate hloov pauv manipulator.

Rau cov khoom siv lithography.

Feature

High purity thiab chemical durability

High Mechanical Strength thiab Hardness

Siab Corrosion Resistance

High Voltage Resistance

Kub kub txog li 1700ºC

Extremly Abrasion Resistance Performance

Kev ua tau zoo ntawm rwb thaiv tsev

Loj loj

Loj loj

| Khoom npe | Chemshun loj loj siab purity Alumina ceramic substrate ceramic vaj huam sib luag |

| Khoom siv | 99.7% alumina hmoov |

| Qhov Loj | 1200x500x20, 1400x900x30, customized loj txais. |

| Xim | Ivory |

| Daim ntawv thov | LCD vaj huam sib luag (PFD, PDF, TFT…) tsim khoom. |

| Min. Order | 1 Pic |

Cov ntaub ntawv tshuaj lom neeg / lub cev

| Chav tsev | 99.7 Alumina Ceramics | ||

| General Properties | Al2O3 cov ntsiab lus | wt% | 99.7-99.9 Nws |

| Qhov ntom | gm/cc | 3.94-3.97 Nws | |

| Xim | - | Ivory | |

| Kev nqus dej | % | 0 | |

| Mechanical Properties | Flexural Strength (MOR) 20 ºC | Mpa(psix10^3) | 440-550 : kuv |

| Elastic Modulus 20ºC | GPA (psix 10^6) | 375 | |

| Vickers Hardness | Gpa (kg/mm2) R45N | >=17 | |

| Khoov zog | Gpa | 390 | |

| Tensile zog 25ºC | MPa (psix 10^3) | 248 | |

| Fracture Toughness (KI c) | Mpa* m^1/2 | 4-5 | |

| Thermal Properities | Thermal conductivity (20ºC) | W/mk | 30 |

| Coefficient ntawm Thermal expansion (25-1000ºC) | 1 x 10^-6/ºC | 7.6 | |

| Thermal Shock Resistance | ºC | 200 | |

| Kev siv kub siab tshaj plaws | ºC | 1700 | |

| Cov Khoom Siv Hluav Taws Xob | Dielectric zog (1MHz) | ac-kv/mm(ac v/mil) ceev | 8.7 ib |

| Dielectric qhov tsis tu ncua (1 MHz) | 25ºC tso | 9.7 ib | |

| Volume Resistivity | ohm-cm (25ºC) | > 10^14 | |

| ohm-cm (500ºC) | 2 x 10^12 | ||

| ohm-cm (1000ºC) | 2 x 10^7 |

Kev pabcuam

Peb txais kev cai txiav txim.

Yog tias koj xav paub ntau ntxiv txog cov khoom lag luam, thov koj xav tiv tauj peb thiab peb yuav them koj cov khoom tsim nyog thiab cov kev pabcuam zoo tshaj plaws!

Khoom cim npe

Sau koj cov lus ntawm no thiab xa tuaj rau peb